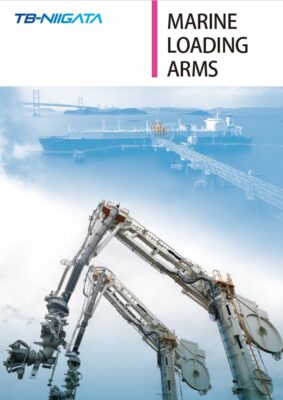

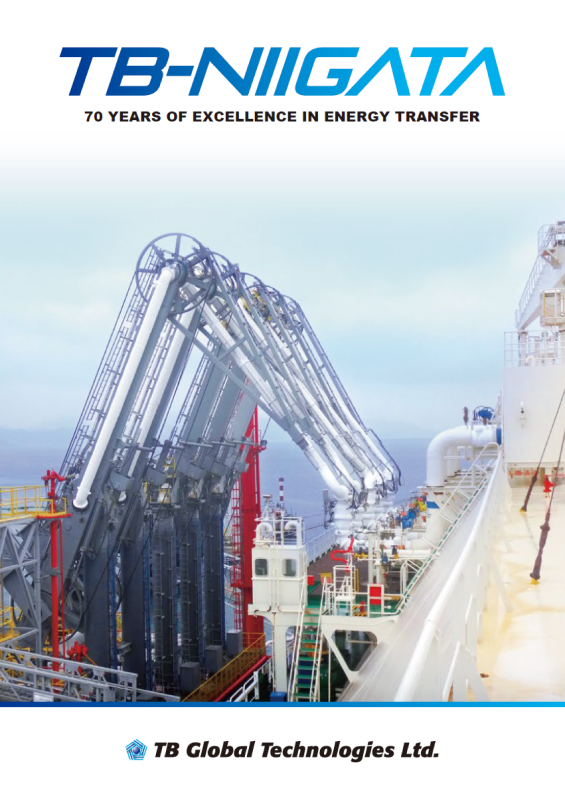

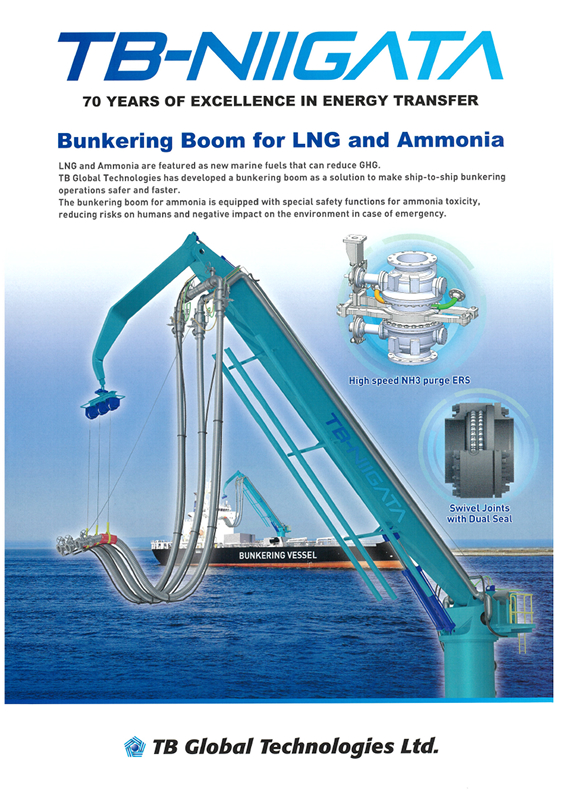

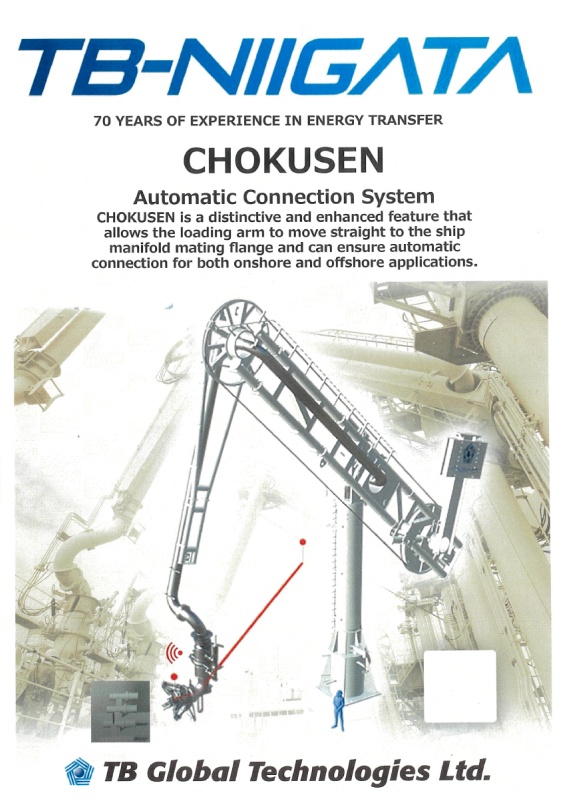

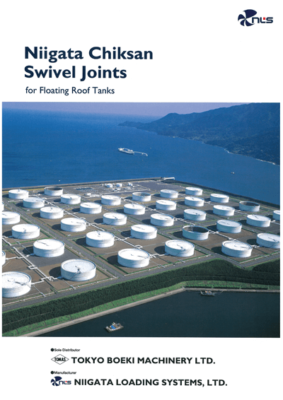

Marine Loading Arm is the equipment that ensures reliable transfer of any type of fluid or gas for maritime transportation. TBG offers a comprehensive portfolio of Loading arms and solutions that meet products specific conditions according to customer's expectations. Our services organization provides: design, manufacture, technical advisory, repair, refurbish, upgrade and supply spare parts.